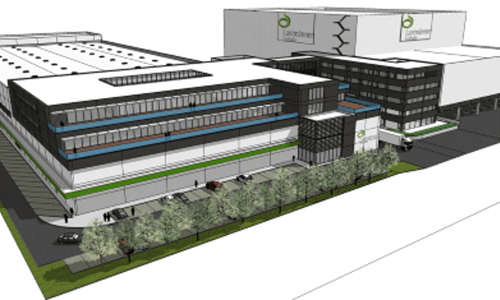

New bakery showcases a sustainable future

Lantmännen Unibake’s energy-efficient bakery in Belgium is a step towards the new 2020 climate

Efficiency is the highest ever at the new Lantmännen Unibake bakery in Londerzeel, Belgium, where the first production line is now running at a capacity of 12,000 baguettes an hour. Everything about the plant is designed to maximise utilisation of energy, minimise waste and make artisanal-style bread of the very best quality.

The resource-efficient technology is also an important step towards the new climate target set this year for the entire Lantmännen group. This aims to cut away 40% of the carbon emissions from production by 2020 – bringing the total carbon reduction since 2009 up to 70%.

“Londerzeel is an example of how we see the future of baking,” says corporate engineering manager Tom Ossieur.

The building is state of the art in terms of insulation, ventilation and air conditioning, and every part of the line is optimised for efficiency, starting with the simplest motor.

Speed, safety and hygiene

Before the new bakery was built, Unibake ran six bakery lines in Londerzeel. The first high-speed baguette line alone has 70% of the old bakery’s total capacity.

According to Tom, it’s the fastest and most efficient baguette line in the world. The factory layout, with designated zones for people, raw materials and specific tasks, ensures a standard of food safety and hygiene that meets the toughest customer and legislative demands.

Eventually, the factory building will hold four high-speed production lines in all.